In today’s highly competitive business landscape, speed, accuracy, and flexibility in product development are more critical than ever. Companies are increasingly turning to 3D printing technology to shorten the product lifecycle, improve customer satisfaction, and unlock faster routes to market share. This evolution is especially apparent in rapid prototyping, where the ability to test, revise, and iterate on a minimum viable product (MVP) can define a company’s competitive advantage.

At RapidPro Manufacturing, we’re at the forefront of these advancements—delivering tailored 3D printing solutions using state-of-the-art tools like FDM, SLA, and Direct Metal Laser Sintering (DMLS). From initial concept to functional prototype and beyond, our services support every stage of new product development.

The Power of Additive Manufacturing in Prototyping

Unlike traditional manufacturing methods, which subtract material through cutting or milling, additive manufacturing builds products layer by layer. This allows engineers to experiment with complex geometries, reduce tooling costs, and iterate quickly—an essential capability in today’s agile software development life cycle and lean product strategy frameworks.

Key Advantages:

- Speed and Flexibility: Develop and test an MVP with real-world functionality before committing to full-scale production parts.

- Cost Reduction: Eliminate the need for expensive molds or tooling, and reduce material waste with targeted support structures and precise extrusion nozzles.

- Customization: Tailor designs to match exact user specifications, enhancing usability, usability testing, and user experience design.

- Market Responsiveness: Respond to target market demand with small-batch production and rapid iteration based on consumer feedback and qualitative research.

Breakthrough 3D Printing Techniques

At RapidPro, we utilize a range of 3D printing systems and techniques to meet varying prototyping needs across industries—from medical device development companies to consumer goods brands and electronics manufacturers.

SLA (Stereolithography)

Developed by Chuck Hull, SLA uses ultraviolet lasers to cure liquid resin into highly accurate, detailed models. Ideal for cosmetic prototypes, mockups, and investment casting patterns, SLA provides a polished surface finish with minimal visible layers.

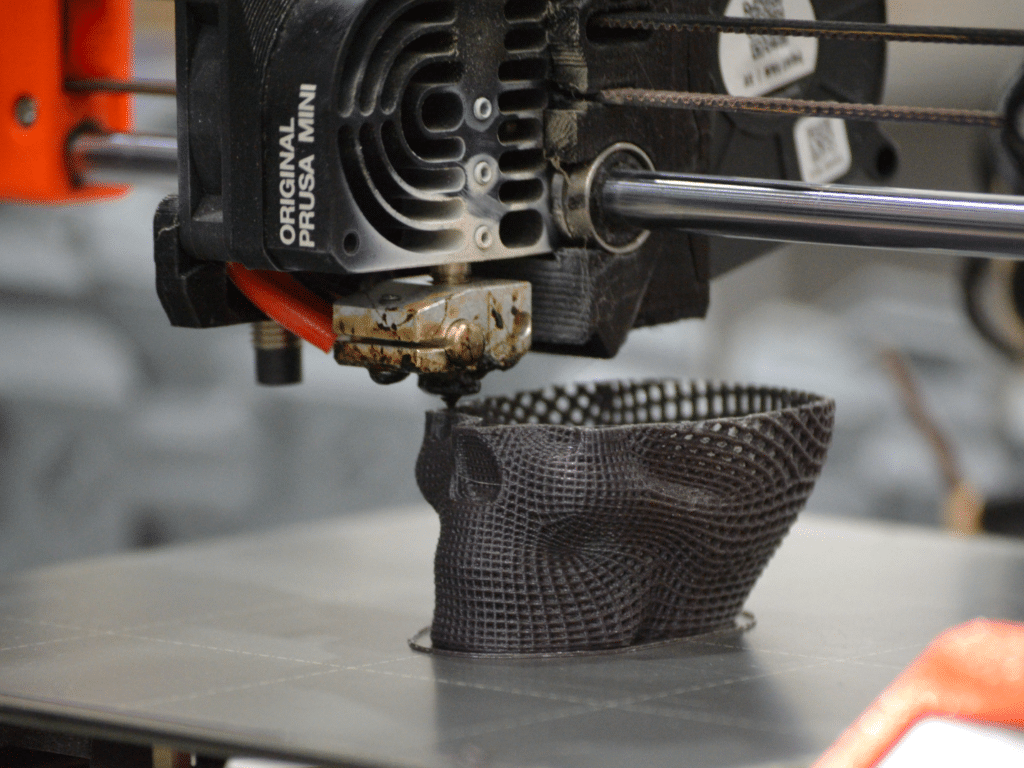

FDM (Fused Deposition Modeling)

Popularized by companies like Stratasys, FDM extrudes thermoplastic materials such as ABS or flame-retardant polymers through a heated nozzle, making it excellent for durable, functional prototypes. It’s widely used in aerospace, automotive, and consumer electronics.

SLS & DMLS (Selective Laser Sintering / Direct Metal Laser Sintering)

These laser sintering techniques use powdered materials (plastic or metal) to form parts without the need for support structures. They’re perfect for medical implants, engine components, and production-grade parts that must meet stringent mechanical and thermal requirements.

Multi Jet Fusion (MJF) and Carbon DLS

Known for speed and detail, MJF and Digital Light Synthesis enable high-volume, functional parts suitable for mass production with improved isotropic properties and reduced risk of defects.

Integrating 3D Printing Into the Product Development Strategy

For modern businesses, 3D printing is no longer just a prototyping tool—it’s a strategic asset. At RapidPro, our services align with best practices in design thinking, business analysis, and product strategy, helping stakeholders test assumptions, validate ideas, and streamline go-to-market efforts.

We support clients with:

- STL file preparation and CAD model optimization

- Access to software tools for iterative development

- Analytics and bench testing to evaluate prototype performance

- Feasibility studies and support for strategic planning

- Guidance on packaging and labeling, especially in consumer products

A Collaborative and Agile Approach

Innovation thrives in collaboration. Using frameworks like Scrum and agile software development, our expert engineers work closely with product design consultants, software development teams, and marketing strategy leads to bring products to life. Our workflow includes regular stakeholder check-ins, prototype evaluations, and continuous improvement based on user research and feedback loops.

Serving Diverse Industries and Applications

Our clients span industries from healthcare and education to automotive, consumer electronics, and industrial manufacturing. Common applications include:

- Functional Prototypes: Used for mechanical testing, usability, and product evaluation

- Visual Models: For marketing, presentations, or customer experience testing

- End-Use Parts: In low-volume production, particularly when speed and flexibility outweigh the economies of mass production

- 3D Scanning and Reverse Engineering: Transforming physical objects into digital designs for innovation or replication

Why Choose RapidPro Manufacturing

As a Longmont-based 3D printing service company, RapidPro offers unmatched expertise, flexible financing options, and transparent pricing—making advanced 3D printing techniques accessible to startups and enterprises alike.

We Deliver:

- Proven experience with 3D Systems, Formlabs, Materialise, and Xometry technologies

- In-depth understanding of innovation management, design methodologies, and best practices

- Seamless transitions from prototype to injection molding and traditional manufacturing processes

- World-class customer service and technical support

Get Started with RapidPro Manufacturing

If you’re ready to shorten your development timeline, reduce costs, and bring your vision to market faster, we’re here to help. Whether you need a functional prototype, a mockup for stakeholder review, or a production-ready part, our additive manufacturing solutions deliver value from idea to execution.

Contact RapidPro Manufacturing today at 970.535.0550 or request an instant quote online. Let’s bring your next big idea to life—with precision, speed, and confidence.