Bringing a product idea to life is an exciting yet complex journey. Fortunately, 3D printing has revolutionized rapid prototyping by enabling designers and engineers to go from digital design to physical prototype faster, more affordably, and with greater precision than ever before. In this blog, we’ll walk through the essential steps of creating a 3D printed prototype—from design concept to finished product—and explore how this technology is transforming the product development lifecycle.

What Is Rapid Prototyping in 3D Printing?

Rapid prototyping refers to the use of digital 3D modeling and additive manufacturing (3D printing) technologies to create physical prototypes quickly and cost-effectively. Unlike traditional subtractive manufacturing, which removes material from a block to shape a part, 3D printing builds objects layer by layer. This allows for greater complexity, speed, and customization.

Why 3D Printing Is Ideal for Prototyping

Speed: Shortens design cycles and reduces time-to-market

Cost-Effective: Eliminates the need for expensive tooling

Flexibility: Easily iterate and refine designs

Precision: Produces high-detail, functional prototypes

Step-by-Step Guide: From Design to Prototype

Step 1: CAD Modeling and Digital Design

Every 3D printing project starts with a detailed 3D model using computer-aided design (CAD) software such as SolidWorks, AutoCAD, or Fusion 360. These tools help engineers define part geometry, tolerances, and mechanical features. The file is then exported in STL format, the most common format for 3D printing.

Step 2: Slicing the Model

Slicing software translates the 3D model into layers and generates G-code instructions for the printer. Users can adjust parameters like infill density, layer height, print speed, and support structures, depending on the prototype’s requirements.

Step 3: Choosing a 3D Printing Technology

Different 3D printing methods offer distinct advantages depending on the prototype’s function:

- FDM (Fused Deposition Modeling): Great for general-purpose prototypes; uses thermoplastic filaments like PLA, ABS, or PETG.

- SLA (Stereolithography): Delivers high-resolution, smooth surface finishes using liquid resin cured by UV light.

- SLS (Selective Laser Sintering): Fuses nylon powder for functional prototypes with mechanical strength.

- DLP (Digital Light Processing) and PolyJet: Ideal for detailed, colorful, or multi-material parts.

Step 4: Material Selection

Material choice depends on factors like strength, flexibility, thermal resistance, and visual appearance. Common materials include:

- PLA and ABS: Affordable and easy to print

- Nylon and TPU: Durable and flexible

- Photopolymer resins: Excellent for fine details

- Carbon fiber and metal composites: For high-performance parts

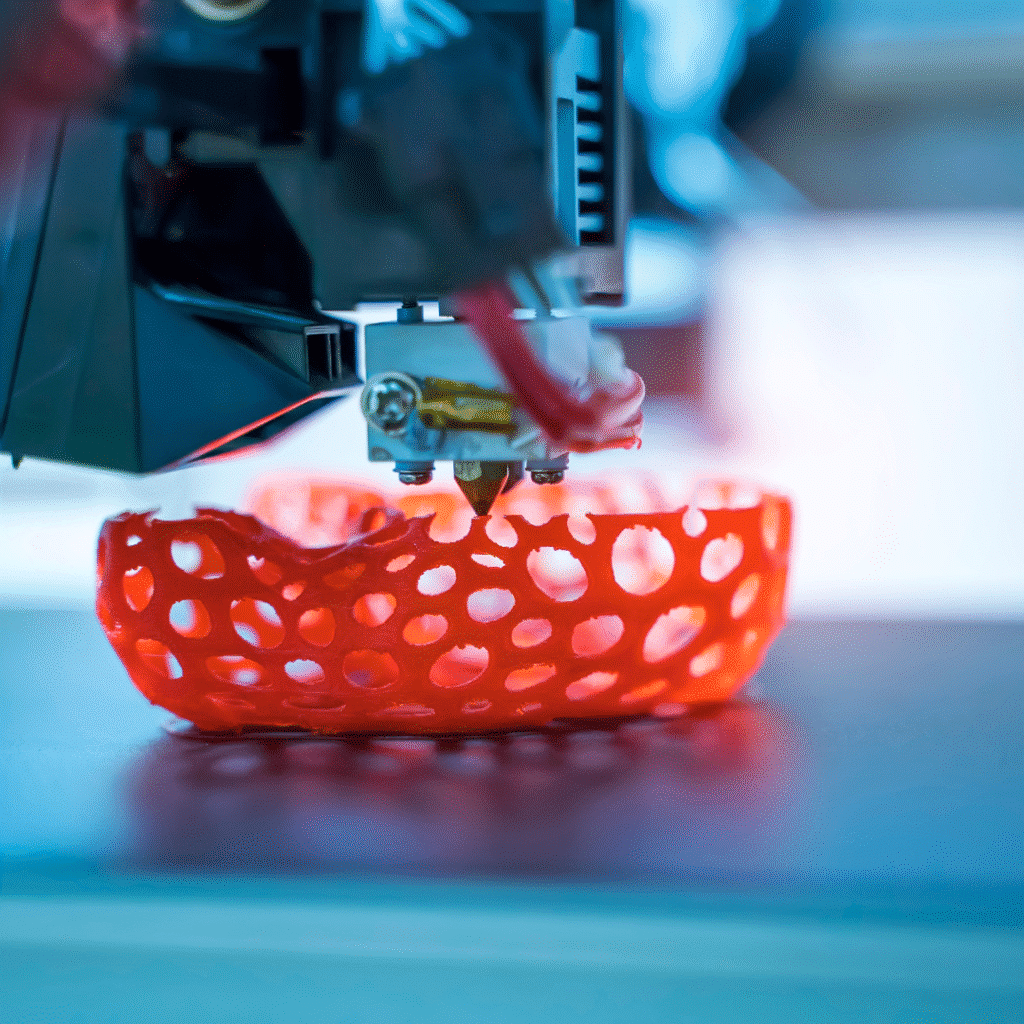

Step 5: Printing the Prototype

Once the design, slicing, and materials are selected, printing can begin. Depending on the printer and technology, print times can range from a few hours to several days.

Step 6: Post-Processing

After printing, prototypes undergo finishing processes such as:

- Support removal

- Sanding or polishing

- Painting or dyeing

- Assembly (if multi-part)

These steps enhance the appearance and functionality of the prototype, making it suitable for presentations or functional testing.

Step 7: Testing and Refinement

With a functional prototype in hand, engineers can evaluate performance, gather feedback, and iterate on the design as needed. 3D printing allows for quick adjustments and reprints, supporting a streamlined development cycle.

Benefits of 3D Printed Prototypes

- Accelerates innovation

- Reduces prototyping costs

- Improves collaboration across design and engineering teams

- Supports user testing and design validation early in the process

RapidPro Manufacturing: Your Partner in Prototyping

At RapidPro Manufacturing, we specialize in providing advanced 3D printing services tailored for product developers, engineers, and innovators. Whether you’re building a proof of concept, a functional prototype, or a production-ready part, our team is here to help you optimize every stage of the process.

Let us help bring your ideas to life—faster, smarter, and more affordably.

Ready to prototype your next big idea? Contact RapidPro Manufacturing today

Frequently Asked Questions

1. What file types are accepted for 3D printing?

STL is the most common file format, but many 3D printers also support OBJ and 3MF.

2. How long does it take to print a prototype?

Depending on the size, complexity, and material, print times can range from a few hours to over a day.

3. Can 3D printed prototypes be used for functional testing?

Yes, with the right materials and technology, many prototypes can be tested for fit, form, and even function.

4. What industries benefit from 3D printed prototypes?

Aerospace, automotive, medical, consumer products, and architecture all use 3D printing for prototyping.

5. Do you offer multi-material or full-color printing?

Yes! We offer a variety of advanced 3D printing methods including multi-material and full-color options.

6. Is 3D printing suitable for low-volume production?

Absolutely. 3D printing is ideal for low- to mid-volume production runs, especially for custom or complex parts.