In the modern world of engineering and manufacturing, few innovations have transformed the design process more than Computer-Aided Design (CAD) software. What began as a tool for creating technical drawings has evolved into a powerful ecosystem supporting complex mechanical engineering tasks, enabling faster development cycles, greater design flexibility, and smarter production decisions.

At RapidPro Manufacturing in Longmont, CO, we use CAD as a pivotal tool to drive every stage of the product development cycle, from digital prototypes to final production. Our in-house engineers leverage CAD to turn ideas into detailed models that transition seamlessly into scalable, cost-effective manufacturing processes.

Precision Engineering with CAD Software

One of the most significant advantages of CAD software is its ability to generate digital models and technical drawings with unparalleled precision. Whether designing small mechanical components or full-scale assemblies, engineers can create 3D models with precise measurements, enabling accurate, production-ready outputs.

This level of detail is crucial in industries like aerospace engineering and automotive design, where even the smallest dimensional variance can affect performance, safety, or regulatory compliance. Using parametric modeling, our engineers ensure that every change in a design is automatically updated throughout the entire assembly model, reducing the likelihood of compatibility issues or overlooked potential issues.

Design Optimization and Simulation Tools

CAD software isn’t just about drawing—it’s a fully integrated engineering tool that supports design optimization, simulation, and analysis. Through finite element analysis (FEA), fluid dynamics, and stress analysis, our team can test and refine concepts in a virtual environment long before any physical objects are produced.

This capability is especially important for validating complex models and intricate designs. It allows us to identify structural weaknesses, optimize designs for efficiency, and explore alternative approaches such as generative design—which uses algorithms to suggest high-performance design configurations based on load, material, and manufacturing constraints.

These analysis tools enhance product safety, reduce material waste, and ensure smoother transitions from design to production.

Driving Innovation Through 3D Modeling and Additive Manufacturing

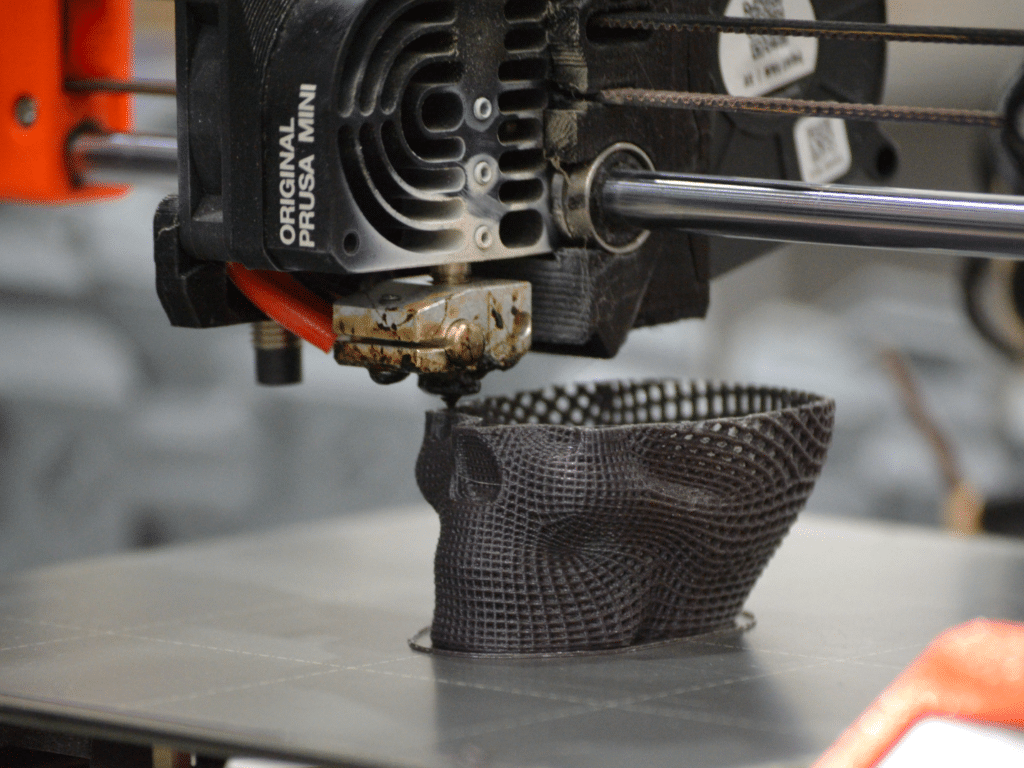

Modern CAD platforms offer extensive 3D modeling capabilities, supporting everything from organic shapes to complex assemblies. At RapidPro, these features enable rapid design iterations and provide digital representations of objects that closely mirror real-world form and function.

When paired with additive manufacturing technologies like 3D printing, these digital designs become physical prototypes in record time. This combination streamlines the transition from design to prototype and allows us to validate complex design concepts quickly and affordably.

Whether you’re testing fit and function, evaluating mechanical strength, or fine-tuning for market launch, our CAD-integrated engineering processes make it possible to deliver innovative solutions faster than traditional methods.

Real-Time Collaboration and Cloud-Based Solutions

In today’s collaborative engineering landscape, real-time collaboration is key to shortening the development timeline and eliminating costly miscommunications. Cloud-based solutions enable multiple engineers, clients, and stakeholders to work together on a single digital model, regardless of physical location.

This collaborative environment reduces project delays, supports global design teams, and ensures that everyone is always working with the most current version of the project. For clients working with external vendors or cross-functional teams, it’s an essential component of smooth, integrated workflows.

From Concept to Completion: Our CAD-Driven Process

At RapidPro Manufacturing, we use CAD to support every stage of mechanical design and engineering, including:

- Detailed consultation and feasibility analysis to assess functionality and manufacturability

- 3D design and parametric modeling for high-accuracy mechanical systems

- Integration of simulation tools for performance validation

- Rapid creation of digital prototypes for early testing

- Seamless design to production integration for low- to high-volume manufacturing

Our CAD workflows allow us to create everything from custom tooling for injection molding to complex assemblies for medical, aerospace, and industrial applications.

The Indispensable Tool for Modern Mechanical Engineers

In a time defined by technological advancements, CAD has become an indispensable tool for modern mechanical engineers. Its ability to produce efficient designs, simulate real-world conditions, and support predictive capability has forever changed how products are created and delivered.

From automotive components to medical devices, our engineers rely on CAD to unlock exciting possibilities in product design, enhance manufacturing efficiency, and support sustainable, cost-effective production strategies.

Bring Your Ideas to Life with RapidPro Manufacturing

Whether you’re developing a new product, refining an existing one, or transitioning into full-scale production, RapidPro’s CAD-driven process is built to support your goals. Our in-house engineers are experts in mechanical design, simulation, and digital modeling—and we’re ready to help you move from idea to reality.

Contact RapidPro Manufacturing today at 970.535.0550 or request a quote online to learn how our advanced CAD software and expert team can power your next innovation.