When it comes to developing cost-effective prototypes that don’t sacrifice durability or function, Fused Deposition Modeling (FDM) remains one of the most widely used and trusted 3D printing methods in the manufacturing industry. Whether you’re a startup looking to test a product design or an established business seeking functional parts at scale, FDM printing offers a practical and affordable path forward.

At RapidPro Manufacturing in Longmont, CO, we specialize in providing high-quality FDM printing solutions that combine strength, precision, and affordability—all backed by years of experience in both additive manufacturing and traditional production processes.

What Is FDM Printing?

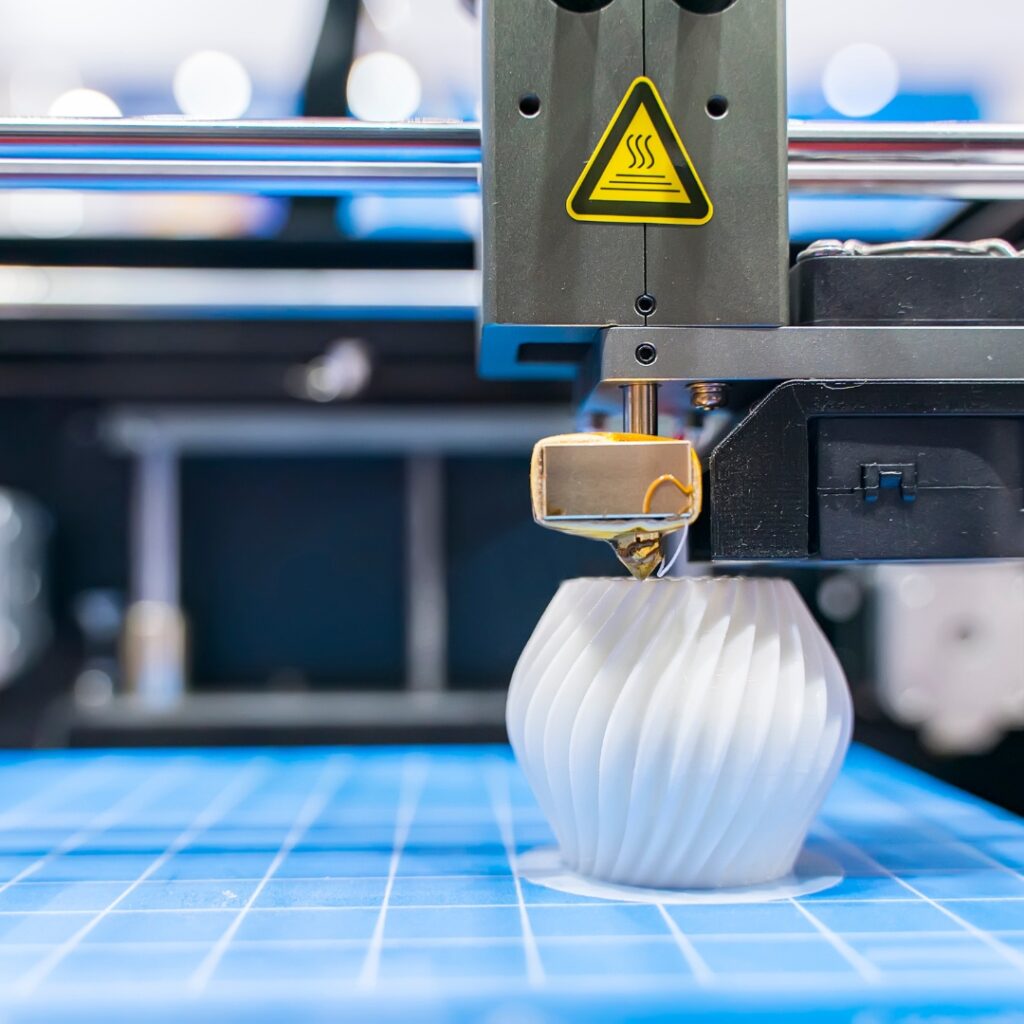

FDM printing, or Fused Deposition Modeling, is an additive manufacturing process where thermoplastic materials are extruded layer by layer through a heated nozzle to build a 3D object. As each layer is deposited, it fuses with the one beneath it to form a solid, durable part directly from a digital CAD file.

This manufacturing technology supports a range of thermoplastic materials and plastic resins, including ABS, PLA, PETG, and nylon, making it ideal for both prototyping and low-volume production runs. Its cost-efficiency, design flexibility, and fast turnaround make FDM printing a key advantage in today’s competitive product development cycles.

Why Choose FDM for Prototypes?

FDM printing offers several benefits for those looking to streamline the product development process:

1. Cost Savings

FDM printing eliminates the need for costly molds, making it an affordable solution for early-stage prototypes and functional test models. This is particularly beneficial for small businesses or startups looking to reduce upfront investment and labor costs.

2. Durability

FDM parts are known for their structural integrity and resistance to heat, impact, and chemicals—thanks to the thermoplastic materials used. This makes them suitable for applications requiring long-lasting, high-strength components.

3. Design Flexibility

Need intricate components or complex internal geometries? FDM printing supports the production of highly detailed parts that would be difficult to create using traditional manufacturing processes.

4. Quick Turnaround Times

Without the need for tooling, FDM projects benefit from shorter lead times. You can go from design to prototype in days instead of weeks, helping you respond to market demands faster.

5. Functional Testing

Unlike aesthetic-only prototypes, FDM-printed parts can be used for mechanical testing and performance evaluation under real-world conditions. That’s a major advantage when iterating on design.

Common Applications of FDM Printing

FDM is a go-to choice for a wide range of industries and applications, including:

Aerospace: Lightweight, chemically resistant components

Industrial Tooling: Jigs, fixtures, and machine parts with mechanical stability

Automotive: Custom test parts and concept models

Consumer Products: Rapid prototypes for usability testing and design refinement

Education and Research: Affordable tools and functional teaching aids

Integrating FDM into Your Production Workflow

FDM isn’t just for standalone parts. At RapidPro, we frequently integrate FDM prototypes into broader product development and manufacturing workflows. Many of our clients use FDM for rapid injection molding prep, concept validation, and iterative design before scaling to high-volume production.

When combined with other technologies like SLA and SLS, FDM offers a complete suite of tooling options tailored to your production process, material needs, and cycle times.

Why Choose RapidPro for FDM 3D Printing?

RapidPro Manufacturing brings deep industry knowledge and precision tools to every injection molding project or 3D printing request. Our FDM services include:

- Access to a wide range of plastic pellets and thermoplastic resins

- Advanced equipment for consistent layer resolution and print quality

- Full support for design modifications and prototype revisions

- Smooth transitions to low-volume or full-scale production

- Fast production cycles and reliable delivery timelines

Whether you need a quick prototype, functional component, or small-batch run, RapidPro delivers high-quality plastic parts with a focus on performance and cost efficiency.

Frequently Asked Questions

1. How durable are FDM-printed prototypes?

FDM parts are made from industrial-grade thermoplastic materials, offering excellent strength, heat resistance, and chemical resistance—ideal for functional testing and real-world use.

2. What types of plastic materials do you use in FDM printing?

We work with a range of materials including ABS, PLA, PETG, and nylon, each chosen based on your project’s required properties like flexibility, impact resistance, or temperature tolerance.

3. Is FDM printing suitable for end-use parts or just prototypes?

While it’s popular for prototyping, FDM can absolutely be used for end-use parts, especially in low-volume production where cost savings and customization are priorities.

4. How fast can I receive my FDM parts?

Depending on complexity and volume, we often deliver parts within a few business days. Our rapid injection molding and 3D printing services are designed for quick turnaround times.

5. Can FDM printing integrate with other manufacturing processes?

Yes. FDM-printed components often serve as bridges to traditional processes like injection molding or CNC machining, helping streamline the full manufacturing process.

Let’s Build Something Functional—Faster

If you’re looking for an affordable, reliable way to produce high-quality prototypes or functional components, FDM 3D printing may be your solution. At RapidPro Manufacturing in Longmont, CO, we offer expert guidance, advanced tools, and a wide range of manufacturing technologies to bring your ideas to life.

Call us at 970.535.0550 or request a quote to get started on your FDM printing project today.