Expertly Engineered and Innovatively Developed Solutions in Fort Collins, CO

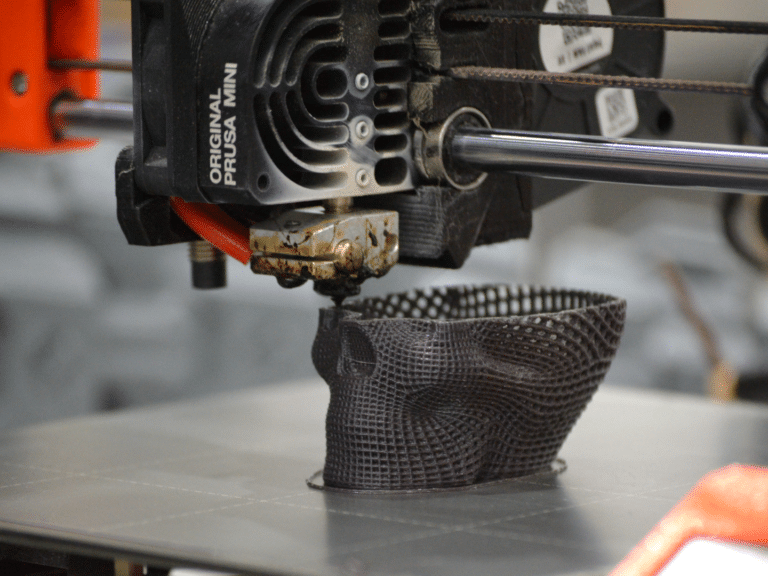

RapidPro Manufacturing helps businesses transform early product concepts into fully realized, production-ready solutions through a structured, high-performance product development process. By integrating advanced technology, engineering expertise, and thoughtful research, we enable clients to bring high-quality products to competitive markets. Our capabilities include high-resolution SLA systems for refined surface detail and durable FDM platforms for functional, mechanical prototypes designed to support real-world testing.

Precision Engineering for Smarter Product Development

Innovative Product Engineering

As a leading provider of mechanical engineering solutions in Fort Collins, our team approaches every project with a commitment to innovation and practical performance. Each design is shaped by technical analysis, market expectations, and the needs of your target audience. We support businesses through new product development, helping them evaluate concepts, refine structural integrity, and ensure alignment with long-term product strategy.

Advanced CAD Technology

Our engineering workflow uses advanced CAD modeling tools for 3D printing that improve accuracy, iteration speed, and manufacturability. By taking a digital-first approach, we reduce design risk, strengthen communication across teams, and streamline transitions into additive or traditional manufacturing. This approach supports early evaluation, enhances productivity, and improves user experience outcomes during prototyping.

Design for Manufacturability and Assembly (DFMA)

Our engineers apply proven Design for Manufacturability and Assembly methodology to reduce production challenges and improve long-term scalability. Each design undergoes structural assessment, risk considerations, and material evaluation to ensure reliability. These practices help companies stay competitive by improving efficiency, lowering production costs, and reinforcing product quality across the full product lifecycle.

Accelerated 3D Printing and Prototyping

RapidPro Manufacturing offers fast, accurate rapid prototyping and manufacturing that shortens development cycles without compromising detail. Our additive technologies support:

- Functional prototypes for mechanical evaluation

- Early-stage minimum viable product testing

- Iterative refinement through agile, feedback-driven processes

- Reliable insights for product development teams preparing for larger production runs

This acceleration empowers organizations to pursue innovation at a pace that aligns with evolving market expectations.

Turning Concepts into High-Performance Products

At RapidPro Manufacturing, we provide engineering and production support that helps Fort Collins organizations progress confidently from idea to finished product. Our teams specialize in strategic planning, market-aligned design refinement, and manufacturing execution supported by industry-leading technology.

Production Solutions

We offer custom mold development, material-driven recommendations, and both low and high volume production pathways. Each solution is tailored to your product development roadmap and informed by careful analysis of performance requirements and market demand.

Collaborative Partnership

Our engineers work closely with clients across industries—including consumer products, industrial applications, and robotics—to deliver dependable outcomes with clarity, accuracy, and speed. This collaborative approach improves customer experience, strengthens stakeholder communication, and ensures that the final product meets or exceeds defined goals.

Creative Innovation

By combining engineering expertise with rapid iteration, we help organizations turn early product ideas into functional, validated components. Our process balances creativity, structured methodology, and technical rigor to produce designs that perform reliably in real-world conditions.

FAQs

We create both aesthetic and functional prototypes using SLA and FDM technologies. These models support early product evaluation, structural testing, and refinement throughout the development cycle.

Our team assists with feasibility analysis, user-informed research, design exploration, and risk considerations to help clients define product vision and prepare for later stages of development.

Yes. We provide DFMA guidance, production tooling, custom molds, and volume manufacturing solutions designed to meet your project specifications and performance criteria.

Absolutely. Our engineers support industries including mechanical systems, industrial equipment, robotics, consumer electronics, and aerospace-adjacent product needs.

Turnaround times depend on complexity and material requirements, but our workflow is designed for efficient iteration and accelerated delivery.

Bring Your Product Vision to Production-Ready Reality

Whether you’re building an early prototype, refining your engineering strategy, or preparing for full-scale production, RapidPro Manufacturing provides the technology, expertise, and collaboration needed to achieve exceptional results.

Contact RapidPro Manufacturing today to begin your path from concept to market-ready product.