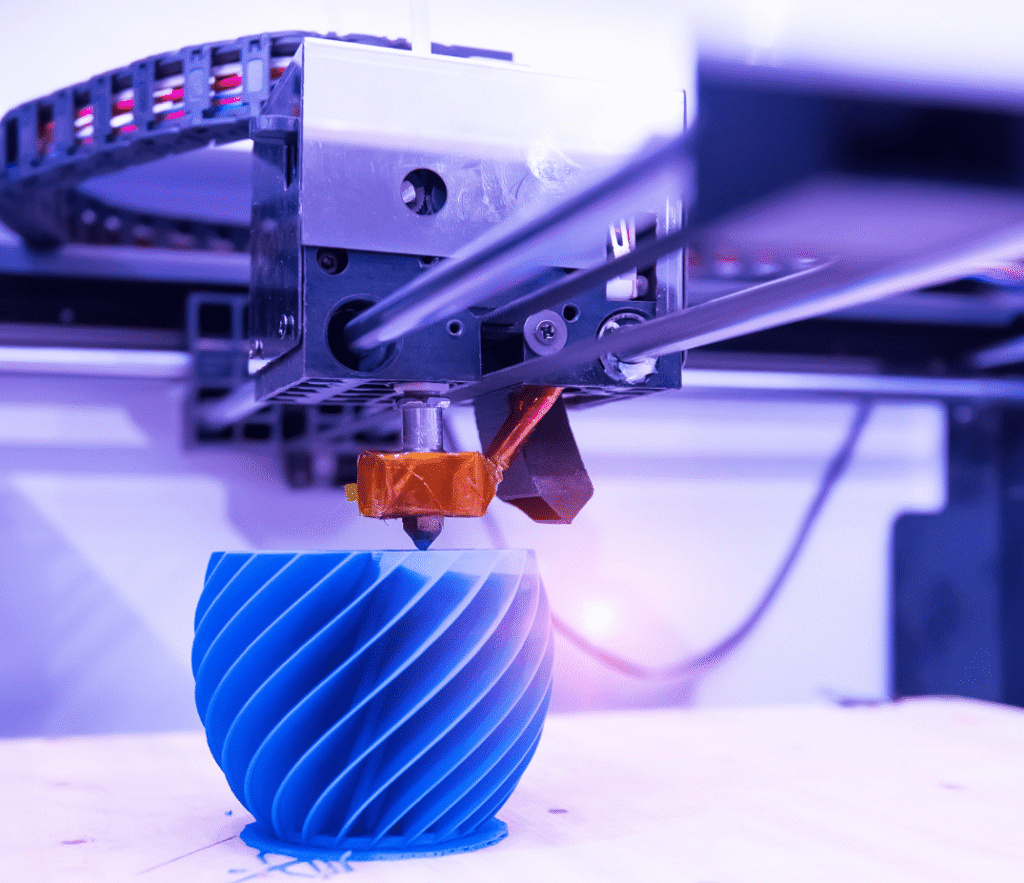

In today’s competitive and fast-moving manufacturing landscape, flexibility and speed are more important than ever-especially for businesses producing limited quantities of specialized parts. That’s where 3D printing, or additive manufacturing, is changing the game. Small-batch production, once hindered by the high cost and long lead times of traditional tooling, now benefits from the affordability, accuracy, and agility that 3D printing offers.

What Is Small-Batch Production?

Small-batch production refers to the creation of products in quantities ranging from a few units to a few hundred. It’s commonly used in industries that require customization, rapid prototyping, or limited-run components. Traditional methods often involve costly tooling and setup processes, which don’t make sense for short production runs. 3D printing eliminates that roadblock, enabling manufacturers to move from design to production faster and more efficiently.

The Advantages of 3D Printing for Small Runs

1. Reduced Upfront Costs

One of the most significant benefits of 3D printing in small-batch production is the ability to bypass traditional tooling altogether. Without the need for aluminum or steel molds, companies can achieve meaningful cost savings-especially during early product development cycles or for low-volume manufacturing.

2. Fast Turnaround Times

3D printing reduces production time by streamlining the transition from digital model to physical part. Once a CAD file is prepared, parts can be printed within hours using SLA, SLS, or FDM technologies. This makes the process ideal for rapid prototyping, small-volume production, and just-in-time delivery.

3. Unmatched Design Flexibility

With no physical mold constraints, manufacturers can produce intricate components and complex geometries that would be difficult or impossible with traditional machining. This opens the door to faster design iterations, lightweight structures, and high-performance parts optimized for function, not manufacturability.

4. Material Diversity for Targeted Applications

Additive manufacturing supports a wide range of thermoplastic materials, resins, and composites with varying mechanical properties, chemical resistance, and heat tolerance. From functional prototypes to end-use parts, the flexibility of materials makes 3D printing ideal for industries like medical devices, consumer products, and automotive components.

5. Sustainable Manufacturing Practices

Because 3D printing is an additive process, it generates minimal waste compared to subtractive methods like milling or CNC machining. This aligns with sustainability initiatives and reduces excess material usage, especially for expensive or limited-supply materials.

Ideal Use Cases for 3D Printing in Small-Batch Production

Product Prototyping: Refine and test design concepts before investing in tooling.

Medical Devices: Create personalized, patient-specific components for testing or end use.

Aerospace & Automotive: Produce lightweight, geometrically complex parts that meet high-performance standards.

Consumer Products: Manufacture customized, limited-edition items quickly and affordably.

Why Partner with RapidPro Manufacturing?

At RapidPro, we specialize in 3D printing services that support small-batch production from concept to completion. Our advanced capabilities-including SLA, SLS, and FDM technologies-allow us to produce everything from rapid prototypes to functional, production-grade parts. We offer:

- Precision builds with smooth surface finishes

- Wide material selection for diverse use cases

- Seamless integration with injection molding and other manufacturing processes

- Scalable production options for startups and established manufacturers alike

Whether you’re developing a new product, need to validate a design, or require high-quality plastic parts in low volumes, RapidPro can help you stay agile and ahead of the curve.

Frequently Asked Questions

1. What makes 3D printing ideal for small-batch production?

3D printing requires no tooling, enabling cost-effective and fast production of small quantities with minimal waste and exceptional design flexibility.

2. What types of materials can be used in small-batch 3D printing?

We support a wide range of plastics, resins, and composites-including ABS, nylon, and high-performance engineering polymers-based on your performance needs.

3. Is 3D printing only for prototyping, or can it produce end-use parts?

3D printing is suitable for both prototyping and end-use applications. Technologies like SLS and FDM produce durable, functional parts ready for real-world use.

4. How does 3D printing support sustainability?

Additive manufacturing reduces material waste by only using what’s necessary to build the part, making it a more environmentally friendly alternative to traditional processes.

5. How fast can I receive my parts from RapidPro?

Our turnaround time depends on part complexity and quantity, but many small-batch projects are completed within a few business days.

Ready to Bring Your Small-Batch Project to Life?

Discover the benefits of 3D printing for agile, on-demand manufacturing. RapidPro Manufacturing in Longmont, CO is your trusted partner for precision prototypes, short-run parts, and product development support. Contact us today to get started.